Jul 07, 2023

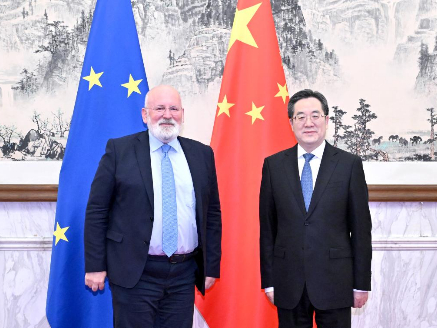

China, EU hold environment, climate dialogue

Chinese Vice Premier Ding Xuexiang, also a Standing Committee member of the Political Bureau of the Communist Party of China Central Committee, and European Commission Executive Vice President Frans Timmermans hold the fourth High-level Environment and Climate Dialogue between China and the European Union, in Beijing, capital of China, July 4, 2023. (Xinhua/Yue Yuewei) BEIJING, July 4 (Xinhua) -- The fourth High-level Environment and Climate Dialogue between China and the European Union was held Tuesday in Beijing, with both sides agreeing to deepen cooperation and play a leading role in global environmental and climate governance. Chinese Vice Premier Ding Xuexiang and European Commission Executive Vice President Frans Timmermans held the dialogue. Ding, also a Standing Committee member of the Political Bureau of the Communist Party of China Central Committee, said that the two sides should implement the important consensus reached by the leaders of both sides, promote China-EU cooperation on environment and climate to achieve more results, and make greater contributions to global sustainable development. Ding pointed out that China attaches great importance to ecological and environmental protection and climate change, unswervingly promotes green and low-carbon development, and has embarked on a series of major measures to ensure the realization of the carbon peak and carbon neutrality goals on schedule. "China is ready to work with the EU to make better use of the dialogue on environment and climate, further build consensus, enhance mutual trust, enrich and expand cooperation, and open up more space for the development of China-EU relations," Ding said, adding that the two sides should tap cooperation potential in renewable energy, green and low-carbon technologies, carbon markets, climate change response, and ecological and environmental protection. The two sides should jointly advance the multilateral process on environment and climate, practice genuine multilateralism, work for the success of the 28th session of the Conference of the Parties to the United Nations Framework Convention on Climate Change, implement the outcomes of the COP15, and join hands in building a community for all life on Earth, said Ding. Timmermans said that the EU and China have played an important role in the global response to climate change. The EU is willing to deepen cooperation with China in addressing climate change, the circular economy, biodiversity protection, and other fields. Chinese Vice Premier Ding Xuexiang, also a Standing Committee member of the Political Bureau of the Communist Party of China Central Committee, and European Commission Executive Vice President Frans Timmermans hold the fourth High-level Environment and Climate Dialogue between China and the European Union, in Beijing, capital of China, July 4, 2023. (Xinhua/Yue Yuewei) (Web editor: Zhang Kaiwei, Liang Jun) Original Link: http://en.people.cn/n3/2023/0705/c90000-20039662.html Posted by...

view more