Common Filter Bag Cage Types and Selection

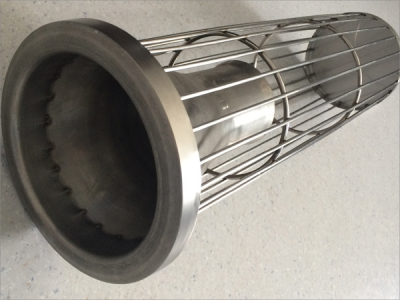

Jun 07, 20231. Stainless steel bag cage: This bag cage is made by stainless steel. When it comes to stainless steel banding, the three most commonly used grades are: Type 201, type 304 and type 316. Here are 3 typical working conditions where stainless steel bag cages are used:

1.1 High-temperature environments: Stainless steel bag cages are resistant to high temperatures and can withstand the heat generated by industrial processes. They are commonly used in applications such as incinerators, power plants, and metal smelting facilities, where the gas streams may reach elevated temperatures.

1.2 Corrosive or aggressive atmospheres: Stainless steel is highly corrosion-resistant, making it suitable for environments where the gas stream contains corrosive elements, such as acidic gases or chemical fumes. Industries like chemical processing, pharmaceuticals, and wastewater treatment often require the use of stainless steel bag cages to withstand these harsh conditions.

1.2 Corrosive or aggressive atmospheres: Stainless steel is highly corrosion-resistant, making it suitable for environments where the gas stream contains corrosive elements, such as acidic gases or chemical fumes. Industries like chemical processing, pharmaceuticals, and wastewater treatment often require the use of stainless steel bag cages to withstand these harsh conditions.

1.3 Heavy-duty industrial applications: Stainless steel bag cages are employed in heavy-duty industries like mining, cement production, and steel manufacturing, where the gas streams carry large amounts of dust and particulate matter. The robust nature of stainless steel allows the bag cages to withstand the abrasive nature of the particles and ensure efficient filtration.

Due to its relatively high cost, many customers choose stainless steel skeletons only in special cases.

↓ ↓ ↓ ↓ ↓

Share your Company info. Get latest price list for stainless steel bag cage.

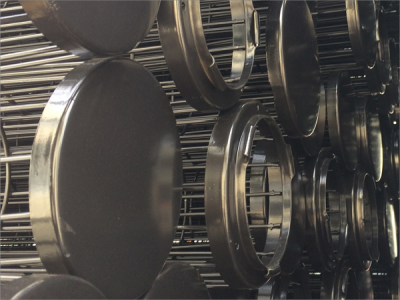

2. Silicone coating bag cage mainly using on working conditions such as:

2.1 Adhesive or sticky dust: Some industrial processes generate dust particles that have adhesive properties, making them stick to surfaces. Silicone coating on bag cages prevents the dust from adhering to the cage, making it easier to clean and maintain the filtration system. Industries like woodworking, pharmaceutical granulation, and certain food processing applications often benefit from the use of silicone-coated bag cages.

2.2 Anti-static requirements: In environments where there is a risk of electrostatic discharge, such as in industries dealing with flammable or explosive dusts, silicone coating can provide anti-static properties to the bag cages. This helps minimize the risk of sparks or ignition that could lead to accidents. Examples of such industries include chemical manufacturing, coal handling, and grain processing.

2.3 Chemical resistance: Silicone coating offers resistance to a wide range of chemicals, making it suitable for environments where the gas stream contains corrosive gases or chemicals. Industries like petrochemical refining, metal plating may use silicone-coated bag cages to withstand the chemical exposure and ensure effective filtration.

Silicone coating provides excellent water repellent properties, making it ideal for applications where high levels of moisture or humidity are present.

↓ ↓ ↓ ↓ ↓

Share your Company info. Get latest price list for silicone coating bag cage.

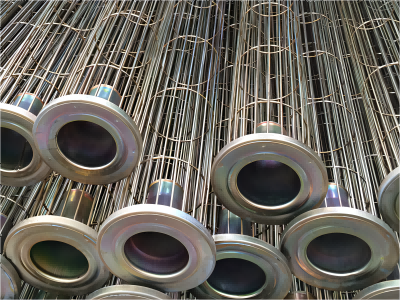

3. Galvanized steel filter bag cage: Galvanized steel filter bag cages are commonly used in various working conditions for dust filtration. Galvanization refers to the process of applying a protective zinc coating to steel, providing several advantages. Here are some examples of working conditions where galvanized steel filter bag cages may be used:

3.1 General industrial applications: Galvanized steel bag cages are widely used in general industrial environments where there is a need for durable and cost-effective filtration solutions. These include applications such as metalworking, mining, cement production, and other heavy-duty industries.

3.2 Moderate to high-temperature environments: Galvanized steel has good heat resistance and can withstand moderate to high temperatures. As such, it is suitable for applications where the gas stream may have elevated temperatures, such as in power plants, incinerators, and some metal processing operations.

3.3 Economical filtration solutions: Galvanized steel bag cages offer a cost-effective filtration solution compared to other materials like stainless steel or specialty coatings. They provide a good balance of durability, performance, and affordability, making them suitable for industries where cost considerations are important.

↓ ↓ ↓ ↓ ↓

Share your Company info. Get latest price list for galvanized steel filter bag cage.

With our expertise and commitment to quality, you can rely on Yuanchen to provide durable filter bag cages and efficient filter bags that optimize your dust filtration system's performance. Choose Yuanchen for reliable and customizable solutions that enhance your dust collection processes.

You can also directly consult our sales engineers for free consultation services regarding your dust collection and denitrification projects.

↓ ↓ ↓ ↓ ↓