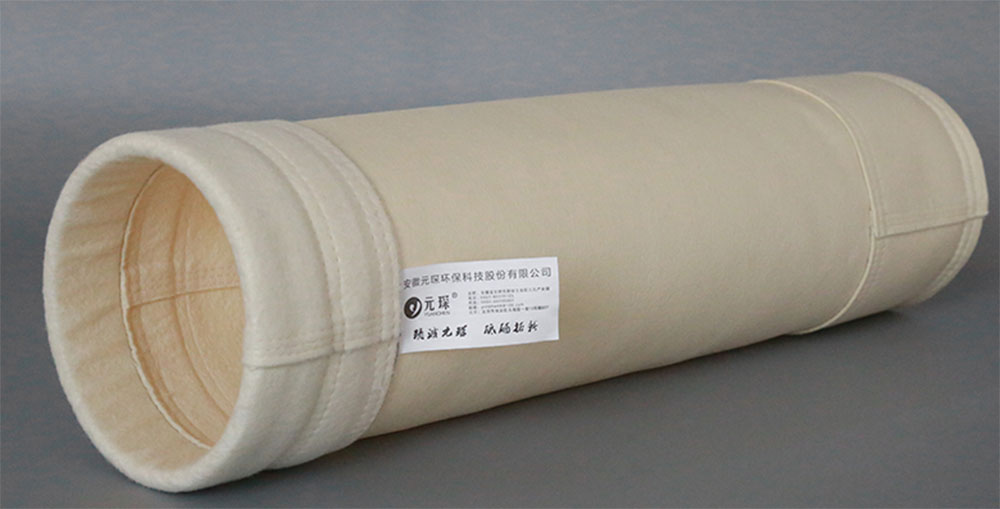

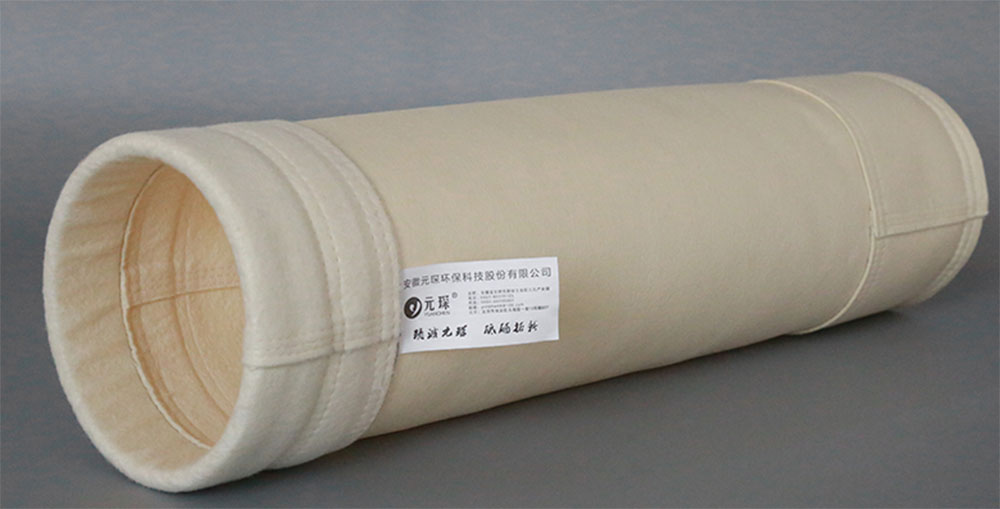

Acrylic needle-punched felt dust-removing cloth bag, the chemical name is polyacrylonitrile, it is used as raw material to make felt by needle punching method, and then through special water repellent treatment to obtain acrylic medium-temperature hydrolysis-resistant needle-punched filter felt, instant working temperature: 160℃, Normal work is 140°C. It is woven with imported fiber, which is a medium temperature material with good acid and alkali resistance and hydrolysis resistance. Needle felt uses acrylic woven fabric as the base fabric to enhance vertical and horizontal strength. It has excellent chemical resistance and hydrolysis resistance, and is widely used in dust collection for waste incineration, asphalt, dryers, coal mills, power plants and other flue gas.

Acrylic fiber needle-punched filter felt dust bag material is imported from abroad. It is a high-performance fiber with excellent heat resistance and corrosion resistance in the medium temperature field. It has flame retardant properties. Compared with ordinary acrylonitrile dust bag, it has higher temperature resistance characteristics. Its continuous working temperature is 130℃, which is better than polyester (polyester) or other acrylonitrile fibers with better resistance to alkali and SO2, O2 , O3 and other gases corrosive. This acrylic dust-removing cloth bag shows good resistance to organic solvents, oxidants, inorganic and organic acids when the temperature is lower than 125. It is not hydrolyzed, so it is particularly important to replace polyester (polyester) needle-punched felt filter bags with finished products in low temperature, chemically corroded and humid places.

The medium-temperature acrylic needle felt dust-removing cloth bag is a plain weave base cloth with a layer of short fibers, the needle is used to vertically move the cloth surface up and down, and the fibers are pierced into the seam of the base cloth yarn with a needle. The base cloth Spread more than two fiber layers on both sides, repeatedly needling to form, and then