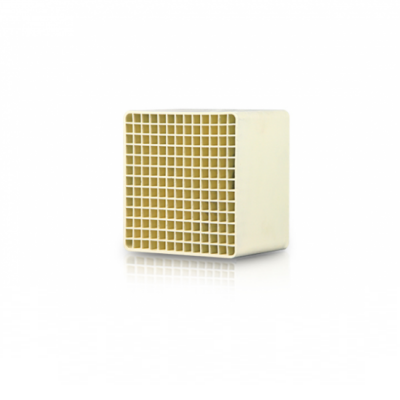

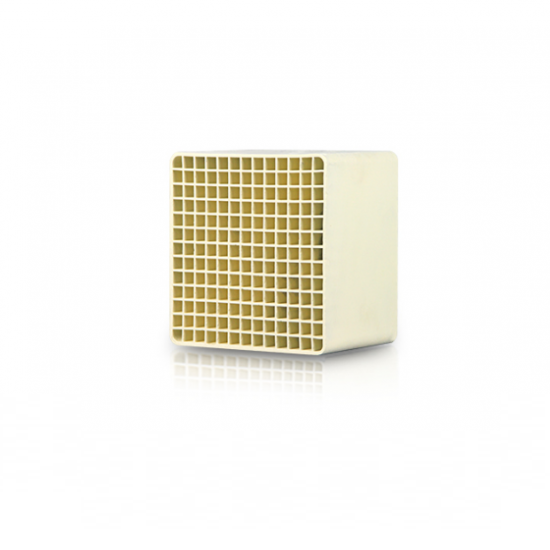

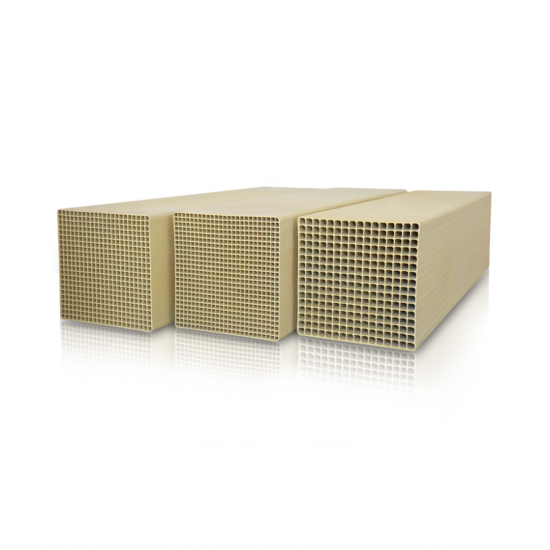

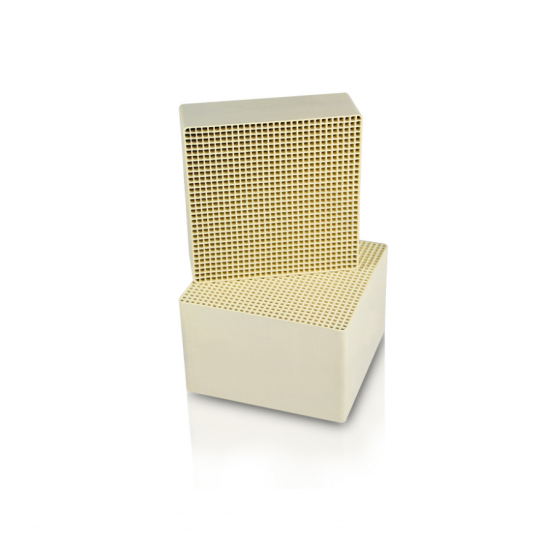

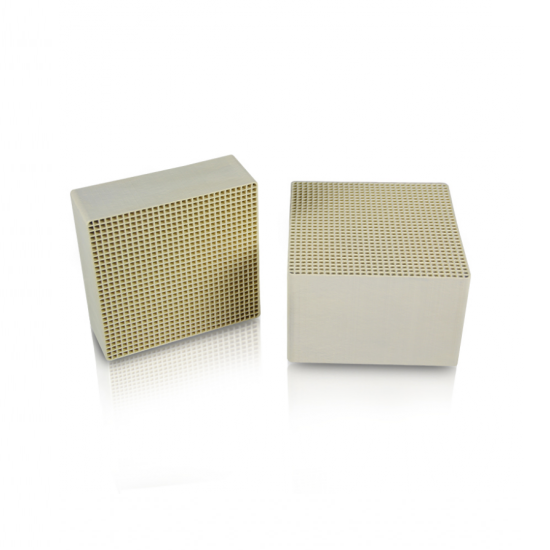

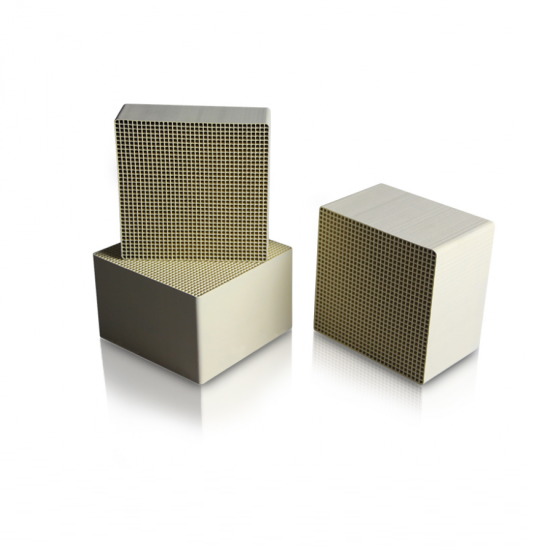

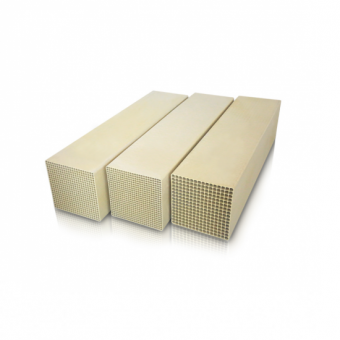

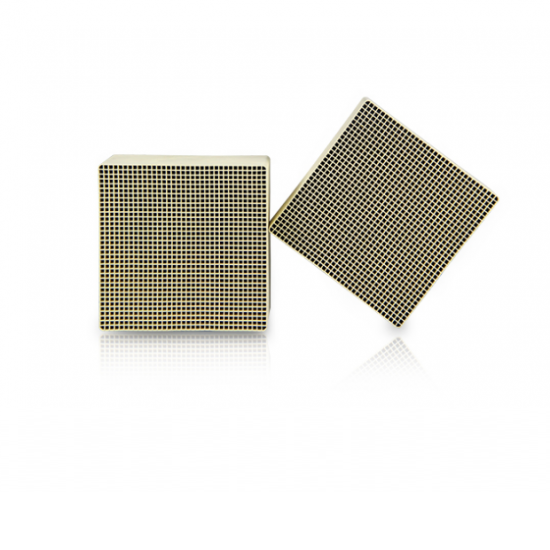

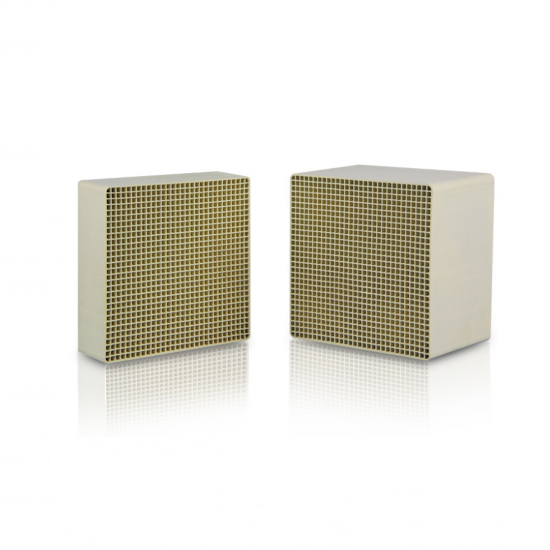

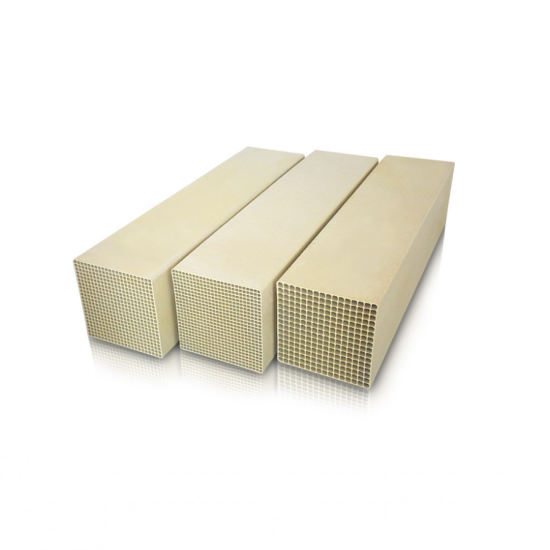

Cement Industry Honeycomb Catalyst

Characteristics of flue gas at the tail end of cement kiln:

1. The dust content in the flue gas can reach 80-120 mg/Nm3.

2. The dust particles are small in size and have high stickiness, making them prone to adsorbing on the catalyst surface.

3. The fly ash contains a significant amount of Ca and small amounts of alkali metals such as K and Na. These elements can reduce the surface activity of the catalyst.

*According to the customer's requirements, we can produce different pitch and formulations of honeycomb SCR de NOx catalyst.