With the advancement of technology, the country's emission standards for atmospheric pollutants are becoming increasingly stringent. YUANSHEN Technology takes the lead in cooperation with well-known domestic universities to develop and experiment with a ceramic fiber-based integrated dust removal and denitration filter cartridge. It achieves ultra-low emissions of dust, nitrogen oxides, dioxins, and other pollutants for various special working conditions.

01 Application fields

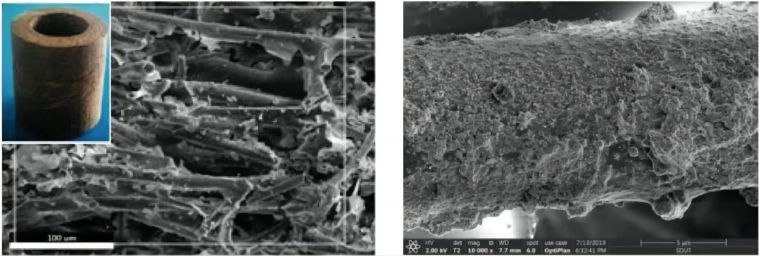

The denitration and dust removal ceramic fiber tube is a filtering element made of ceramic fiber composite material and loaded with a nanometer denitration catalyst system based on environmentally friendly rare earth precious metals. It can be used in building materials, chemical, metallurgical, and waste incineration industries to meet the comprehensive emission standards for dust, nitrogen oxides, and sulfides in the country's air pollution.

02 Dust removal and denitration principle

Dust particles are trapped on the surface of the fiber tube, and the clean and up-to-standard flue gas is discharged from the inner wall of the fiber tube under the suction of the induced draft fan after passing through the multi-porous element and being catalyzed by the catalyst to reduce nitrogen oxides to nitrogen and water.

SCR reaction mechanism of denitration catalyst

In the reaction temperature range (200-450℃), NH3 is stably adsorbed on the surface of the denitration catalyst. At the same time, this catalyst has strong NO oxidation and adsorption ability, so there are multiple paths for the SCR reaction on this catalyst:

Reaction 1: 4NH3(ad) + 4NO(gas) + O2 → 4N2 + 6H2O

Reaction 2: 4NH3(ad) + 4NO(ad) + O2 → 4N2 + 6H2O

Reaction 3: NO(ad) + O2 → NO2

Reaction 4: 4NH3(ad) + 2NO(ad) + 2NO2(ad) → 4N2 + 6H2O

03 Product technical advantages

Compared with existing technologies, this technology has the following advantages:

(1) High porosity, low gas resistance, high filtration accuracy: the filtration efficiency of particles, NOx, dioxins, etc. can reach over 99.99%, and the NOx removal efficiency can reach over 95%, with high filtration accuracy to meet the national atmospheric emission standards.

(2) Inorganic fiber materials, not easy to burn. Insensitive to sparks, eliminating the high-temperature burning and fire hazards of traditional filter media. The highest temperature resistance can reach 900℃, and it can be used for a long time at 500℃, with excellent temperature fluctuation resistance.

(3) Stable product performance, acid and alkali corrosion resistance, long service life: The composite structure of the ceramic fiber filter tube avoids the flexibility of the bag, and the dust removal effect is better. At the same time, it avoids the hidden danger of pasting the bag. Its service life can reach 5-8 years, greatly exceeding the life of filter bags, reducing maintenance costs and operating expenses.

(4) Can achieve dry desulfurization, dust removal, and denitration integration: the high porosity of the ceramic fiber filter tube can load a catalyst inside. Ceramic fiber filter tubes with catalytic functions can achieve dry desulfurization, dust removal, and denitration integration. Pure dry flue gas purification technology compared with wet desulfurization has no smoke tail, no need for bleaching, no desulfurization wastewater, and no secondary pollution.

04 Conclusion

As an environmentally friendly technology enterprise, Yuanchen Technology has accumulated rich experience in the fields of industrial dust removal and denitrification, and regeneration of waste and old denitrification catalysts, and has occupied an important position in the atmospheric pollution control industry. In the future, Yuanchen Technology will continue to respond to the national call, fight for the protection of the blue sky, and make its due contribution to the protection of blue waters and blue skies, and the construction of a beautiful China.