Denitrification catalysts refer to catalyst used in SCR (selective catalytic reduction) denitrification systems in power plants, where the SCR reaction causes a chemical reaction between the reducing agent and the nitrogen oxides in the flue gas selectively at a certain temperature. The most commonly used catalysts are the V2O5-WO3(MoO3)/TiO2 series (TiO2 as the main carrier and V2O5 as the main active ingredient).

The current SCR commercial catalysts are basically TiO2 as the carrier, V2O5 as the main active ingredient and WO3 and MoO3 as the antioxidant and anti-toxicant auxiliary ingredients. There are three types of catalysts: plate, honeycomb and corrugated plate.

The

plate catalyst is based on a stainless steel sheet pressed into a metal mesh, with a mixture of TiO2 and V2O5 adhered to the stainless steel mesh, which is pressed and forged to form the catalyst module.

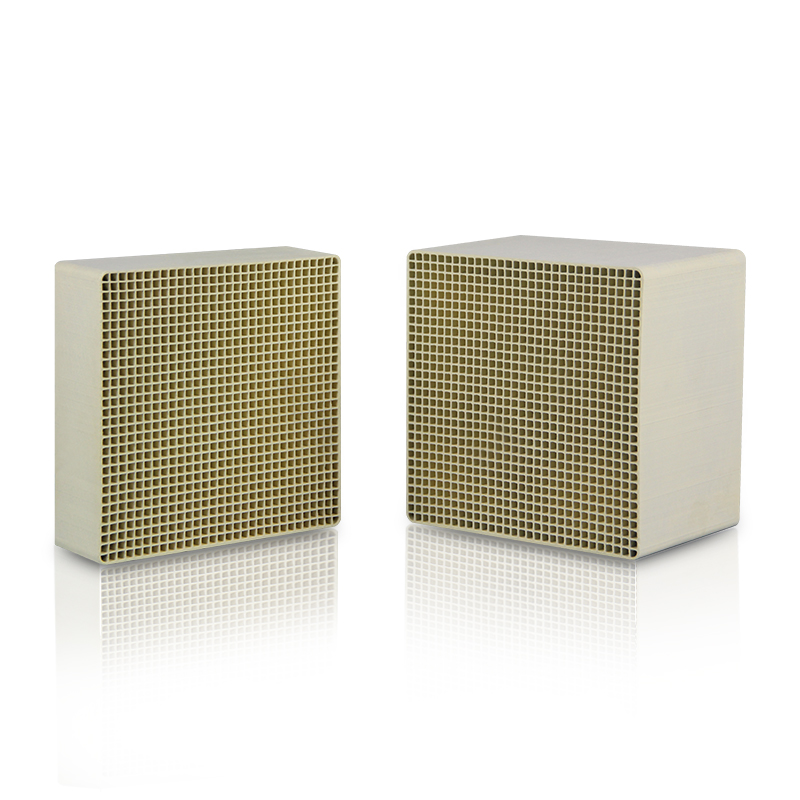

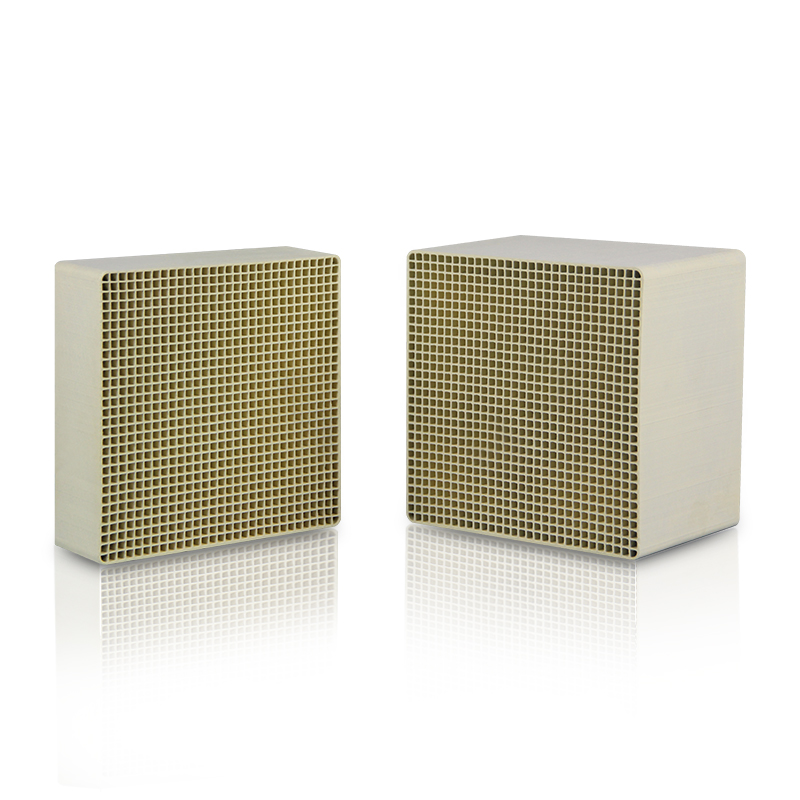

Honeycomb catalysts are generally homogeneous catalysts. The mixture of TiO2, V2O5, WO3, etc. is passed through a ceramic extrusion equipment to make catalyst elements with a cross section of 150mm X 150mm and varying lengths, which are then assembled into standard modules with a cross section of approximately 2m X 1m.

The manufacturing process for corrugated plate catalysts is generally based on TiO2 reinforced with glass fibres and the active ingredients such as WO3 and V2O5 are impregnated onto the surface of the catalyst to increase the catalyst activity and reduce the SO2 oxidation rate.