The active component of commercial SCR denitrification catalysts is V2O5, the carrier is TiO2 of anatase type and WO3 or MoO3 is used as a co-catalyst. the composition and proportion of SCR catalysts varies according to the content of components in the flue gas and the guaranteed denitrification performance.

The active component is the main body of the multi-catalyst and is a necessary component without which the required catalytic effect is lacking. The co-catalysts themselves are inactive or have little activity, but can significantly improve catalyst performance. Both WO3 and MoO3 have been found to improve the thermal stability of catalysts and to improve the electronic interaction between V2O5 and TiO2, increasing the activity, selectivity and mechanical strength of the catalyst. In addition to this, MoO3 also enhances the catalyst's resistance to As2O3 poisoning. The carrier mainly plays the role of supporting, dispersing and stabilising the catalytically active material, while TiO2 itself also has a weak catalytic capacity. TiO2 of the anatase type was chosen as the carrier for the SCR catalyst. Compared with other oxide (e.g. Al2O3, ZrO2) carriers, TiO2 has a strong ability to inhibit SO2 oxidation and can well disperse the vanadium species on the surface and the semiconductor nature of TiO2.

The ideal coal-fired flue gas denitrification catalyst needs to meet the following conditions: (1) high activity, in order to meet stringent national emission standards, a denitrification rate of 80% to 90% is required, i.e. a high SCR activity of the catalyst is required; (2) high selectivity, the reducing agent NH3 is mainly oxidised by NOx to N2 and H2O, not by O2. The high selectivity of the catalyst helps to improve the utilisation rate of the reductant and reduce operating costs; (3) good mechanical properties, as most coal-fired power plants use a high ash arrangement, the SCR catalyst needs to be subjected to long-term abrasion by high airflow and dust, and the installation process also requires a certain degree of mechanical strength of the catalyst; (4) strong resistance to toxicity, as flue gas and fly ash contain a high level of toxins, the catalyst needs to be resistant to long-term toxic (5) Other, low oxidation rate of SO2, good chemical, mechanical and thermal stability, large specific surface area and good pore structure, low pressure drop, low price and long life for SCR catalysts. In addition, SCR catalysts are required to be simple in structure, take up less space and be easy to disassemble or fill.

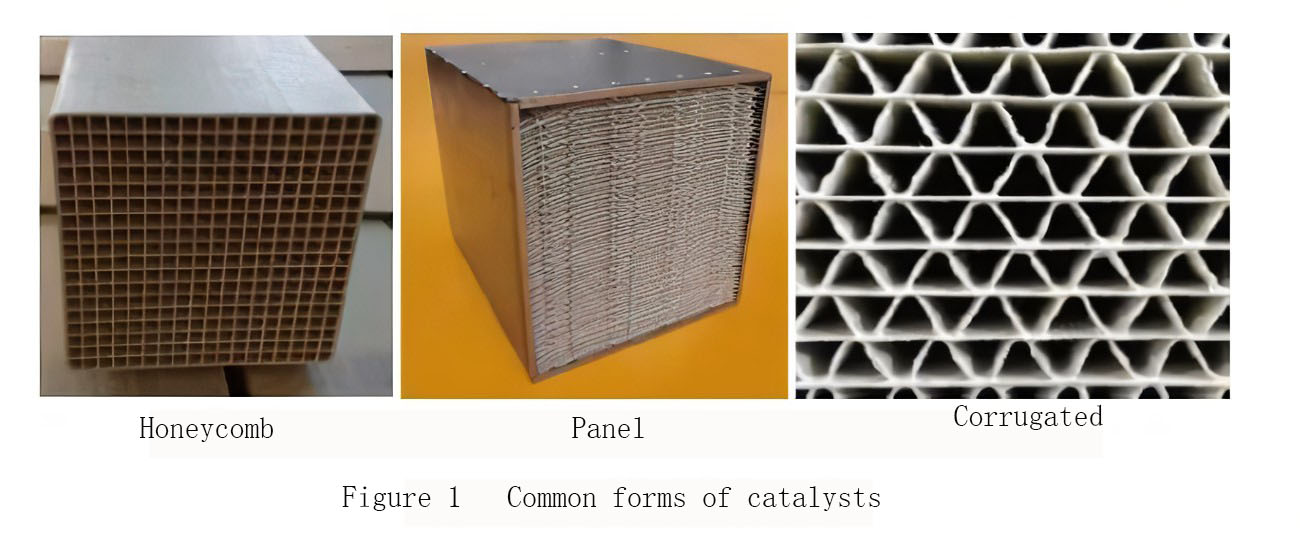

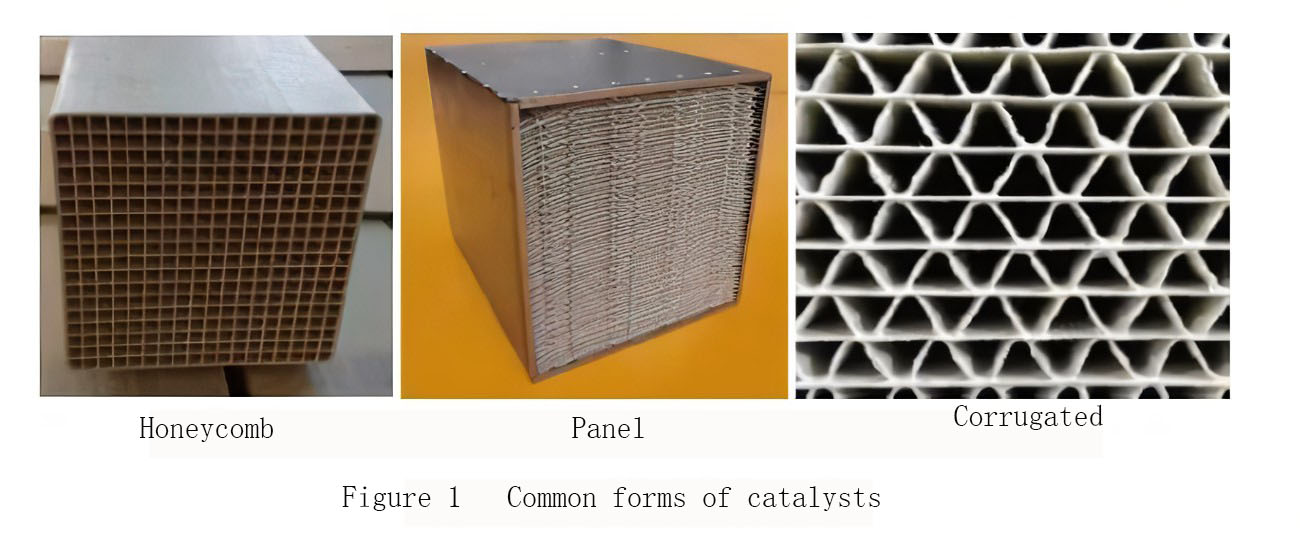

The main types of power plant flue gas denitrification catalysts are honeycomb, panel and corrugated, with the structures shown in Figure 1. Honeycomb catalysts, with their large surface area, high activity and small size, currently occupy 80% of the market share, by flat plate catalysts and the least corrugated plates.