In the process of filter bag work, the problem of filter bag damage often occurs, mainly including abrasion, burning, corrosion, etc., among which the filter bag burning is mainly related to dust and flue gas. This article will analyze the filter bag from the above two aspects. The cause of the burning problem and provide corresponding solutions to prevent the filter bag from burning in advance.

1. Dust

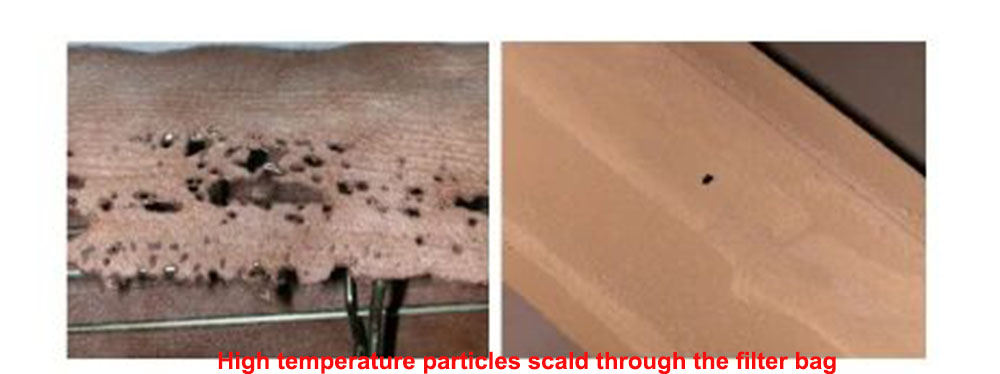

①High temperature

There are high-temperature particles of different sizes in the filtered high-temperature flue gas, and their temperature is greater than 400℃, which cannot be detected by ordinary temperature detectors; most of the high-temperature particles will settle in the gravity sedimentation chamber, and some of them will pass through the flue gas at high speed with the airflow. The pipe enters the dust collector. For polyester, polypropylene, acrylic, polyphenylene sulfide and other fiber filter bags, when the surface of the filter bag is less dusty, the high-temperature particles will burn through the filter bag to form irregular round holes; when the surface of the filter bag is more dusty, the high-temperature particles will not Scalding through the filter bag will form dark-colored baking marks on the filter bag

②Combustibility and chargeability

Certain combustible and easily loadable dusts, such as coal powder, coke powder, alumina powder and magnesium powder, meet sparks in the air (usually caused by friction sparks, static electricity, etc.) under certain concentration and oxygen content. Sparks, combustible particles, etc.) will burn or explode. The shock wave generated at the moment of the explosion deforms the porous plate, the filter bag bursts, and the instant high temperature and fire cause the filter bag to burn. The flammability of dust is related to many factors such as particle size, composition, concentration, combustion heat and combustion speed. The smaller the particle size, the larger the specific surface area, and the easier it is to ignite.

③Dust heat storage

When dealing with high-temperature flue gas, a large amount of dust will accumulate in the ash hopper. If it is not cleaned up in time, the dust will accumulate heat in the ash hopper and increase the temperature. Excessive temperature will bake the filter bag and cause the filter bag to harden or burn, or even burn the bag. For cages and ash hoppers, the dust in the chamber should be cleaned up in time at this time.

④Dust smoldering

When the dust on the surface of the flame-retardant fiber filter bag is oily and adhesive, it is easily ignited by high-temperature gas or particles. At this time, the flame-retardant fiber on the surface of the filter bag burns without open flames, and the oily dust sticks to the surface of the filter bag It burns slowly and without an open flame. Generally, the burning traces are diffuse or wavy edges, and there is no trace of high-temperature baking.

2. Smoke

Improper control of high-temperature flue gas will cause large fluctuations in temperature. When the temperature exceeds the use temperature of the filter bag seriously. When the ignition point of the filter bag is reached, the filter bag will burn and break.

In response to the burning problem of the above-mentioned filter bag, Yuanchen Technology provides different types of flame-retardant filter media solutions in combination with domestic blast furnace gas coal mill dust collection, cement plant coal mill dust collection and other industry needs.

If the filter bag is burned by high-temperature particles, you can choose a flame-retardant filter material with flame-retardant fiber added on the surface; when the dust is flammable and chargeable, you can choose to add conductive fiber, antistatic agent, flame retardant, etc. Flame-retardant filter material; when the dust is oily and adhesive, you can choose a flame-retardant filter material with waterproof and oil-proof functions. When the flue gas temperature fluctuates greatly, the high-temperature filter material can be selected according to the "continuous long-term use temperature" and "instant short-term temperature".