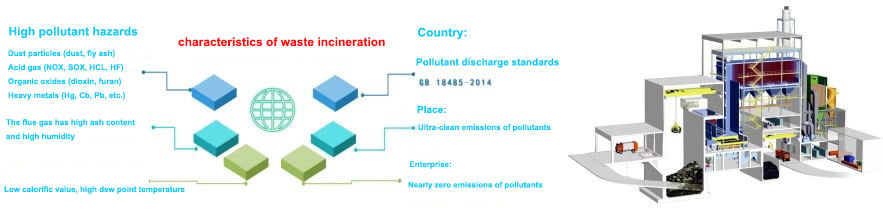

The composition of the flue gas from domestic waste incineration is complex. In addition to O2, N2, CO2, H2O, etc., it also produces pollutants such as acid gas (NOx), CO, heavy metals, dust and residual organic matter (including dioxins and furans, etc.).

The characteristics of the flue gas of waste incineration are: 1) The flue gas contains a large amount of moisture, which generally has a moisture content of 23% to 30%. The original water content in the garbage is large, and some hydrocarbons generate water vapor during the combustion process; 2) The composition of the flue gas is complicated. Contains O2, SOx, CO2, Nox, HCl, HF, water vapor, total hydrocarbons (THC), and produces carcinogens such as dioxins and furans; 3) The characteristics of flue gas dust are different from others. The salt content (chloride and sulfate) in the dust is high, the particle size of the flue gas dust is fine, and the flue gas dust has a high viscosity; 4) It contains trace heavy metals such as mercury, cadmium, lead, molybdenum, chromium, nickel, and copper.

These conditions make the material requirements of the dust removal filter material for the flue gas of domestic waste incineration higher, and need to withstand high temperature and high humidity working conditions, and at the same time need to withstand the long-term erosion of complex flue gas.

The special filter material for waste incineration flue gas treatment is mainly PTFE+PTFE membrane filter material, that is, PTFE fiber is used as the main raw material, and PTFE base cloth is placed in the middle layer to form a "fiber layer-base cloth-fiber layer" structure. After acupuncture processing and special functional treatments (calendering, water and oil repellent, chemical corrosion resistance, antistatic, heat setting, etc.), a filter material with certain physical and chemical properties is formed. Finally, the surface of the needled felt is covered by a high-temperature hot pressing process. Layer PTFE membrane.

|

Product name |

Ptfe+ptfe filter fabric |

Ptfe+ptfe filter fabric with membrance |

|

fiber |

PTFE |

|

|

scrim |

PTFE |

|

|

Weight(g/m2) |

750-850 |

|

|

Continuous temperature resistance(℃) |

260 |

|

|

Peak temperature resistance(℃) |

280 |

|

|

Break strength(warp) |

>800 |

|

|

Break strength(weft) |

>800 |

|

|

Elongation at break(warp)% |

<20 |

|

|

Elongation at break(weft)% |

<30 |

|

|

Air permeability(m3./m2/min) |

8-12 |

2-5 |

|

Wind speed(m/min) |

<1.2 |

<1.0 |

|

scope |

High temperature resistance, oxidation resistance, excellent acid and alkali corrosion performance, high temperature, low filtration accuracy requirements |

High temperature resistance, oxidation resistance, excellent acid and alkali corrosion performance, and high filtration accuracy requirements |

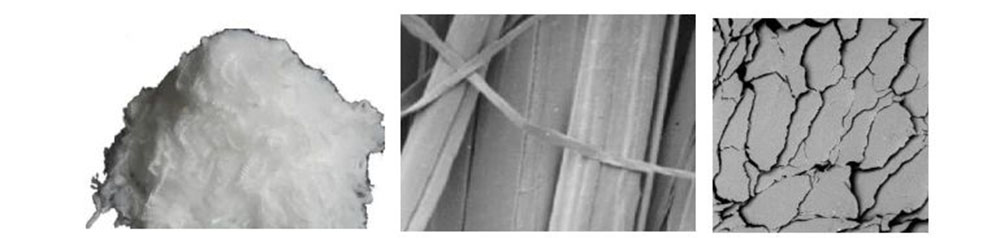

Polytetrafluoroethylene (PTFE) is a highly crystalline polymer of tetrafluoroethylene (TFE) monomer. It is a white and waxy thermoplastic. The special molecular structure of PTFE makes the fiber have excellent chemical stability and corrosion resistance, which can improve the chemical erosion of the filter material. In addition, the PTFE fiber has excellent temperature resistance, and the long-term use temperature can reach 260°C. Therefore, PTFE fiber is widely used in the field of waste incineration flue gas particulate matter treatment.

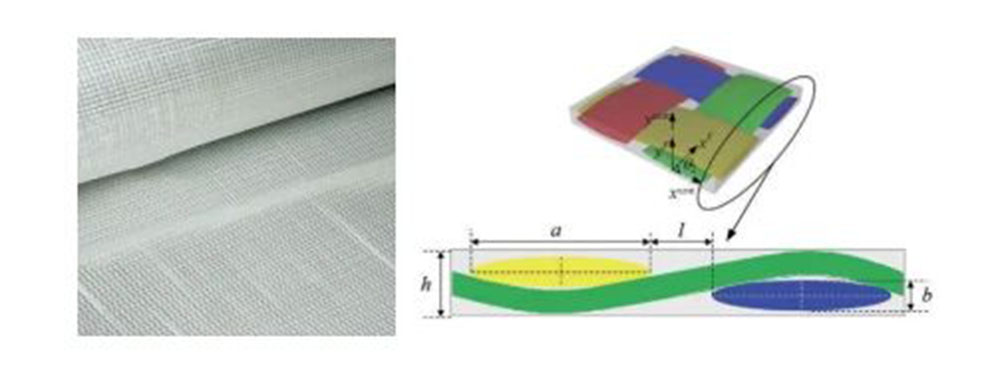

The PTFE base fabric retains all the characteristics of the PTFE material, and is interwoven with warp and weft in a plain weave structure, which not only provides strength for the PTFE filter material, but also supports the overall structure of the filter material, and can be interwoven with metal wires to provide the filter material with antistatic properties Wait.

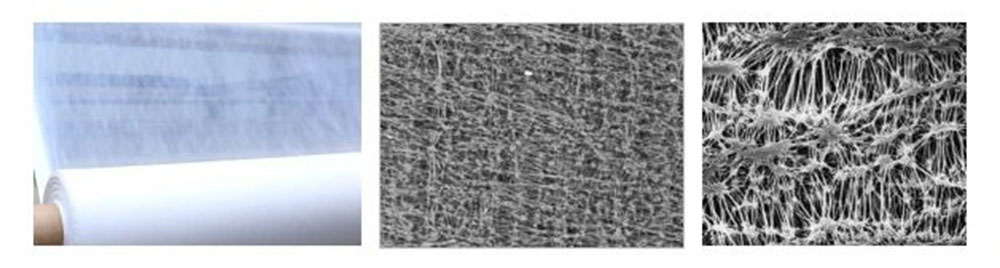

PTFE microporous membrane has all the characteristics of PTFE material. Using the "high efficiency and low resistance" membrane technology independently developed by Yuanchen Technology, it is firmly combined with the PTFE fiber filter material, which can effectively improve the filter performance of the filter material to meet 5 mg/ Ultra-low emission of Nm3.

In the future, Yuanchen Technology will continue to stay true to its original aspiration, move forward, actively respond to the call of the party and the country, tackle the development and application of biodegradable materials, and regard it as its responsibility to achieve the goals of "carbon peak" and "carbon neutrality". , To make new and greater contributions to the world's environmental friendliness and human health!