Filter Bag Cage with Filter Bag to Remove Dust

Product Description

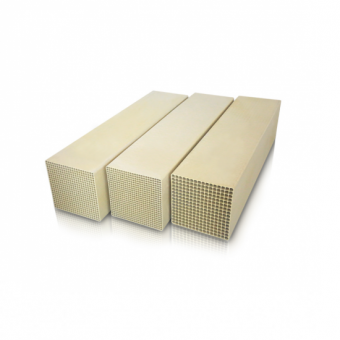

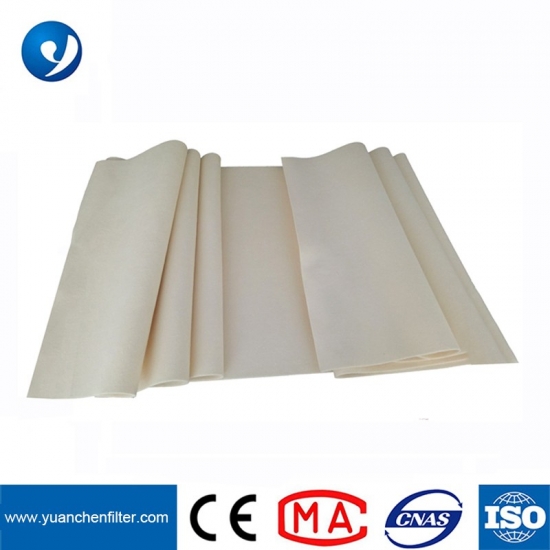

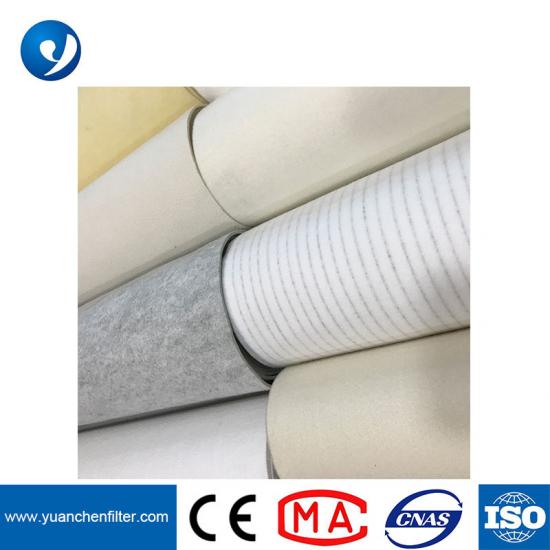

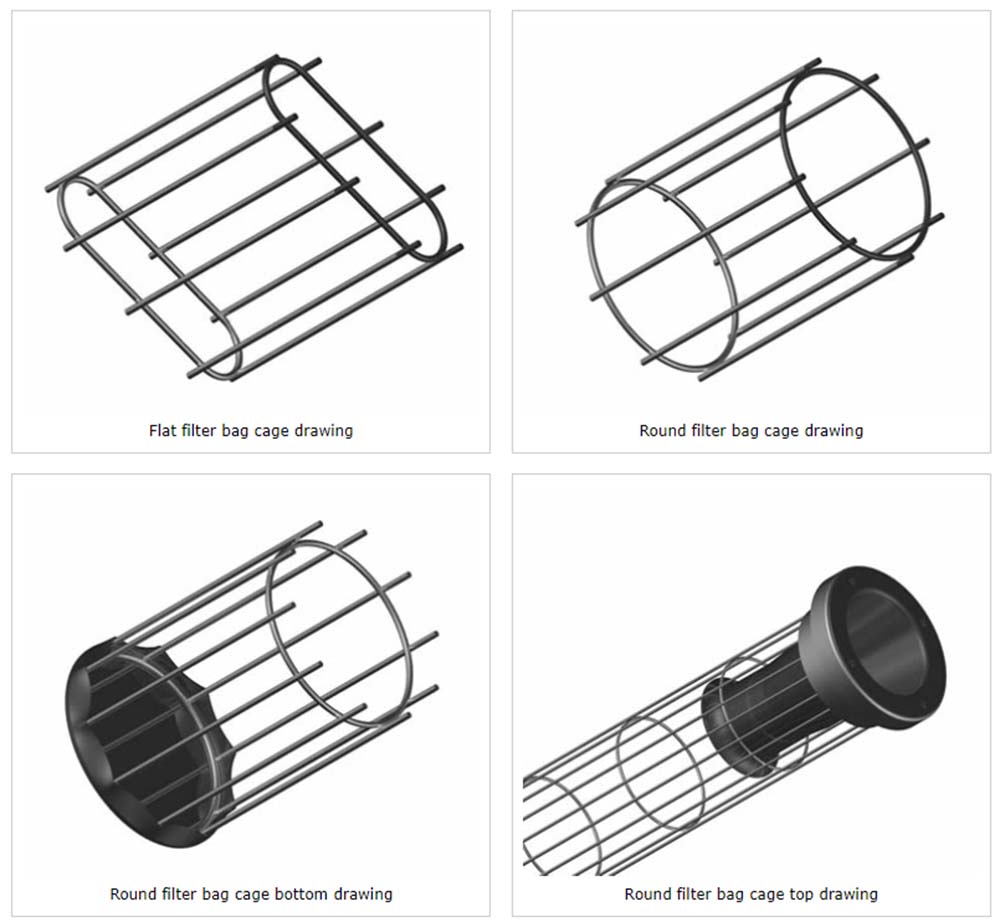

Filter bag cage also named dust collector cage is made of stainless steel or carbon steel with galvanization, silicon coating, epoxy or PVC vinyl coating finish. It is a kind of strong cage which works with filter bag to remove dust efficiently. This cage uses the advanced hot-melt jointing technology. The jointing method of bag bottom, side and collar ring all are hot-melt welded, that can avoid the pinholes from seam filter bag. Its construction consists of vertical and horizontal wire. The horizontal wire can be round, flat or envelop shape which is welded smoothly with vertical wire. So this cage shape can be round, flat, envelop. Besides, Its connection way can be clamp, chuck, claw join, guide plate connection. It is light and easy for installation and maintenance.

More baghouse filter bag cage display

Industrial dust collector bag supporting filter cages with venturi tube

Specification:

Material: carbon steel, galvanized steel, 304 stainless steel, 316 stainless steel, 316L stainless steel.

Wire diameter: 3mm, 3.2mm, 3.5mm, 3.8mm, 4mm, 5mm.

Horizontal bar type: round, envelop, flat.

Vertical wire number: 8, 10, 12, 16, 20, 24.

Ring space: 15.24cm or 20.32cm.

Cage diameter: 100mm - 200mm.

Style of connection: clamp, chuck, claw join, guide plate.

Surface treatment: galvanization, silicon coating or epoxy, PVC vinyl coating.

Note:The vertical bar, horizontal ring, spacing ring, length, the diameter of the ring and the shape of the cage can be according with the requirement from client.

Dimension Recommended for filter bag cages and venturi

A.Round Style

|

ΦDiameter |

Bag Diameter |

Length |

|

115 |

120 |

2000 2400 2800 3200 3600 4000 4400 4800 5200 5600 6000 |

|

125 |

130 |

|

|

147 |

152 |

|

|

195 |

200 |

B.Flat Style

|

Perimeter |

Bag Perimeter |

Length |

|

800 |

800 |

2000 3000 4000 |

|

900 |

900 |

5000 6000 |

C.Envelope Style

|

Length Width Thickness |

Bag Length Width Thickness |

|

1500*750*25 |

1500*750*25 |

How to install Industrial Dust Filter Flame Filter Bag Cage?

1) Handle with care during installation, do not throw, do not drag on the ground, etc., so as not to damage the surface of the bag cage and the interface snap ring.

2) The cage has three sections, the upper, the middle, and the lower section. When installing, two people must cooperate. First put the next section into the filter bag carefully. When leaving a certain length, insert the steel bar into the bag cage, and then use the steel bar to move the lower section of the bag cage. Hang on the flower board. Then one person holds the upper section bag cage with both hands, and the other person inserts the pin into the pin hole.

3) After the upper and lower bag cages are connected, check whether they are connected firmly and whether the plug is inserted into the pin hole.

4) The whole bag cage frame is slowly lowered into the filter bag, and it is never allowed to quickly impact the bottom of the bag. If there is any abnormal blockage, find out the cause before inserting it.

5) Check the contact between the head cover of the bag and the flower plate. The contact between the head cover and the flower plate should be good. If there is a large looseness, carefully check the reason.

6) After the bag cage is installed, check the distance between the bottom ends of the filter bags, and adjust the distance between the bottom ends of the filter bags in the clean air chamber by rotating the bag cage to ensure that the bottoms of the filter bags do not collide with each other.

7) After installing the filter bag cage, all the packing boxes, membranes, installation tools and other materials must be taken out of the clean air chamber. Objects are not allowed to fall into the installed filter bag cage. , Should be removed in time.

Package of Industrial Dust Filter Flame Filter Bag Cage

We provide all kinds of standard export packing for cargo protection. The dust bag filter will be fixed on the container. The filter bag and cages will be fixed in corrugated box and steel framed structure.

Application of Mild Steel Dust Filter Bag Cage

Application:

- Mine industry.

- Medicine industry

- Plastic, food industry.

- Coal fired power stations.

- Steel power station.

- Cement industry.

- Paper industry.

- Building and construction industry.

- Other industrial segments.

FRQ

Q: Are you a trading company or a manufacturer?

A: We have our own factory.

Q: Do you support OEM made?

A: OEM is warmly welcomed, we can arrange your own color or label, print your OEM package, and make your own shape according to your drawing.

Q: Do you provide samples ? is it free or extra?

A: Yes, we could offer the sample for free charge, you only have to pay the cost of freight.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: How's the after-sale service?

A: We’ll take photos for your check before loading container and confirm all of documents within 48 hours after shipment. For any other supplier order,you just ask them to deliver us for combine container,we’ll do this favor to arrange everything very well.

Q: What is your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shipment.

Please feel free to contact us if you have any questions.