1.Material selecting

When selecting filter material,above all ,the operating conditions should be considered.What is the temperature of the flue gas?

Is the smoke and dust moist or oily?

Is the flue gas corrosive and acid-base?

2.Size Selecting

You only need to use calipers to measure the diameter of the holes in the dust collector panels and provide them to us.We can select the most suitable specifications for your bag housing.If it is not installed,we will be responsible for you.

3.Measure the length

Find acrylic dust collector bag,measure the length up to down,or measure the length of the bag housing.

2. We pay attention to following processing matters:

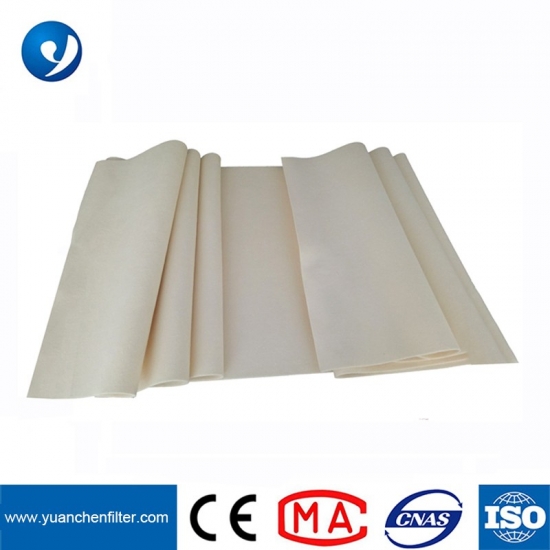

(1) Precise design required size of the filter cloth for filter bag parts, the filter cloth will larger than the actual amount design size, to leave a spare for weaving.

(2) To choose the right filter bag accessories, specifications and check its quality. The filter bag accessories should match the filter bag quality requirements.

(3) We make the filter bag line drawing, cutting, sewing on automatic production line. When the filter bag need manual processing, we will open it on the operation platform, and with certain pulling force to keep it is flat.

(4) We keep the strict processing quality standards, according to design drawings and operation process. Our worker meet the requirements of tooling and clothing , no smoking.

(5) We have the responsible for the processing of products, and examines, waste, residue, defective goods in the beginning.

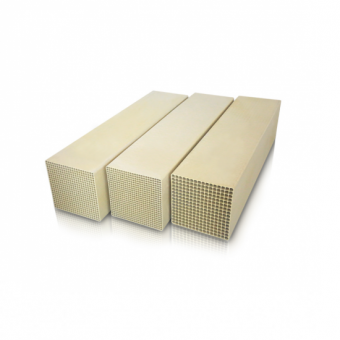

Technical Specification

Name/Quality

100% acrylic w/ PTFE membrane

Component

Shell Fiber

100% Acrylic (DT)

Scrim

100% Acrylic (DT)

Weight

550g

Thickness

2.0mm

Air Permeability /127Pa cm3/cm2.s

4

Tensile Strength N/5*20CM

Length

≥800

Cross

≥1000

Elongation at break %

Length

≤25

Cross

≤35

Temperature ℃

Continue

125

Peaks

140

Finish

Heat Stabilization,Glaze, Singe, PTFE macerate,PTFE Membrane

Use Scope

Cenment, Steel, Construction,Metallurgy;

3. Remarks

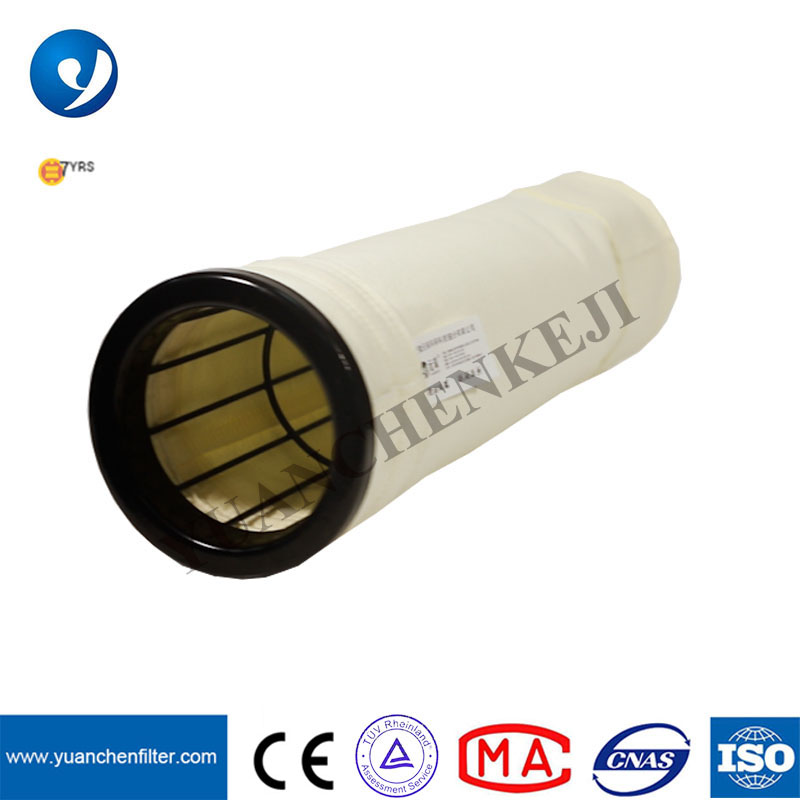

1) The length of acrylic baghouse filter bags: can be customized

Usual size: diameter 100mm, 125mm, 130mm, 150mm, 180mm, 250mm ect.

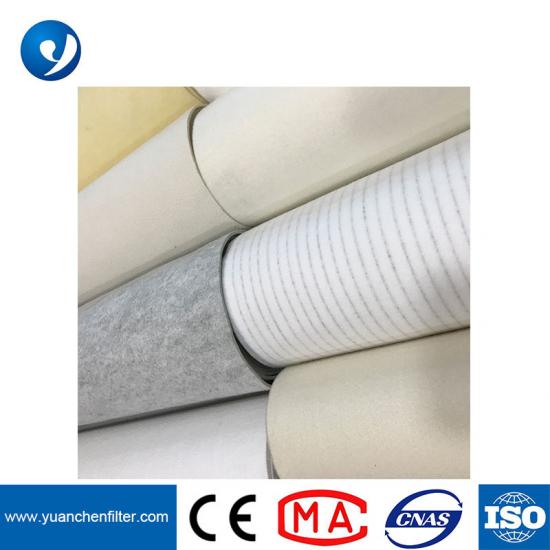

2) Process Method: automatic sewing or welded

3) Prodction details:Double bottoms and reinforcement to make abrasion resistance.

Sewing thread: PTFE thread, polyester thread.

4) Inspection: Filter bags will be according to the national standards, industry standards and enterprise standards.

5) If your required filter bag is different from our usual one, then please send us your drawing picture and choose material you need since we also produce the nonstandard filter bag.

4. Advantages of Us:

1.Various material: Polyester(PE), Polypropylen(PP), Aramid, P84, Acrylic, PPS, Fiberglass, PTFE, Nomex, FMS etc

2.Strong intensity

3.Excellent anti-abrasion,good finishing treatment

4.Good raw material, competitive price

5.High filtration efficiency

6.Fast delivery

7.Size can be customized

8.Factory manufacturer could control quality and price

9.Strict quality inspection and contol

10.Professional designer teams to match with your operating condition

5. Application field:

In industry dust collection

- Power Plant Or Stations

Filtered dust, waste incineration, Flue ash, discharging flue ash,Coal dus

-

Building and Construction

Cement, iron and steel ,furnace dust, gypsum, limestone, finely ground quartz,

Calcium hydroxide, lead monoxide, quicklime, acid crystals, Pure clay, phosphates, magnesite concentrate, finely ground ,fluorid, production of aluminum

- Chemical Industry

Thomas meal (Fertilizer) ,Rubber compounds, sinter dust, catalysts ,Sodium sulfate Soap powder

6. The acrylic dust collector filter sleeves packaging:

Different types of filter bag must be individually packaged. In general, it is wrapped in plastic bags for water proof, then put in a carton. Filter bag must be neat and regular packing, with the ring of the filter bag to avoid ring flat compression deformation. For the requirement to keep the shape of filter bag, it must fill padding for filter bag inside. Any other packing ways also be accepted up to you.

7. FRQ:

Q: Are you manufacturer?

Yes . We are .

Q : Can you provide free sample if we need ?

Yes . We will provide you sample at soonest . It's our pleasure to service you .

Q : Can you produce product according to our drawing or print our logo ?

Yes . We can .

Q : How about the delivery lead time ?

Lead time for normal products will be about 15 days after payment received .

Q; What's your means of transportation ?

Ocean shipping , courier , air etc , based on customer's requirements .