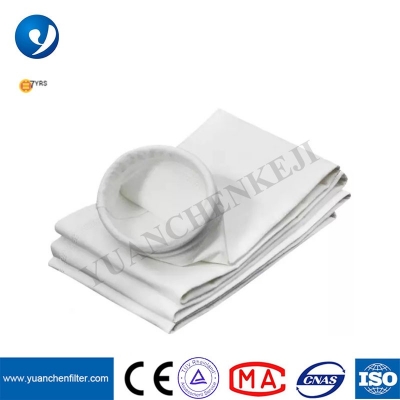

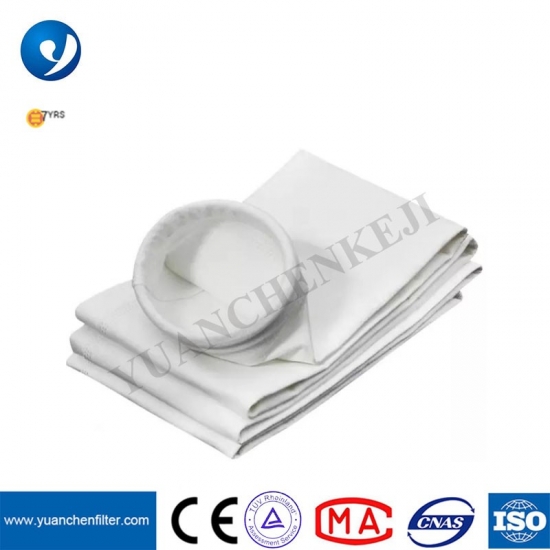

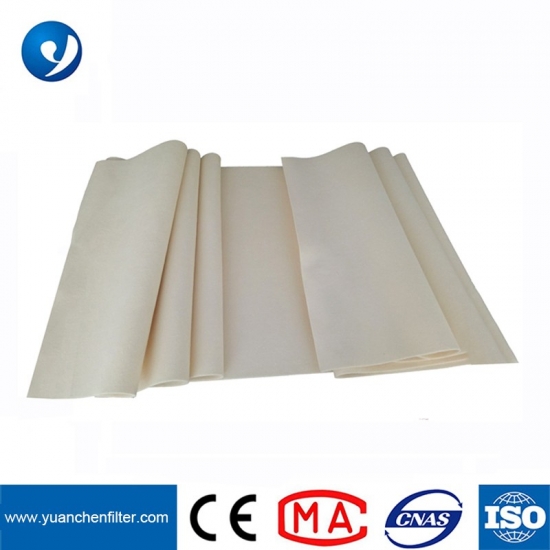

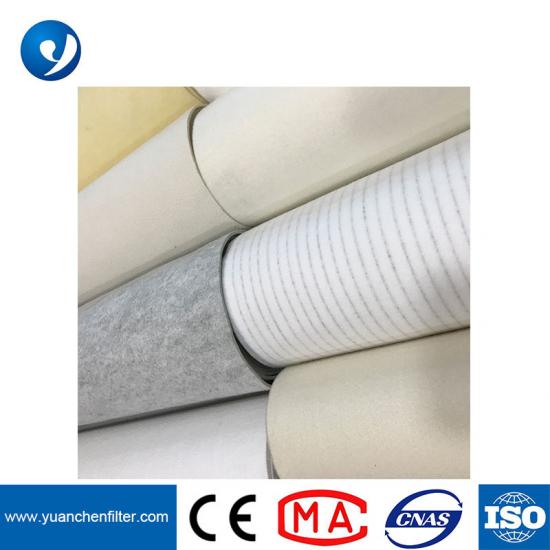

Industrial dust collector cloth bag normal temperature needle felt dust removal filter bag

Specifications

The working principle and steps of the circular dust bag filter are as follows: the dust-containing gas enters the filter chamber through the open flange set on the ash hopper, the coarser dust particles fall into the ash bin, and the gas containing fine dust is filtered through the filter bag. Dust is retained on the surface by the filter bag. Then the clean gas filtered by the cloth bag flows into the clean air chamber through the mouth of the bag, and then is discharged into the atmosphere through the fan. When the dust on the surface of the filter bag accumulates more and more, the programmer, that is, the pulse controller, starts to work. The pulse valves are opened one by one, and the compressed air used for cleaning dust is sprayed to clean the filter bag through the nozzle set on the injection pipe, so that the filter bag suddenly expands. Under the action of the reverse airflow, the dust attached to the surface of the filter bag quickly leaves the filter bag and falls into the ash bin, and the dust is discharged by the ash unloading valve.

Application

* Asphalt – Durable construction required for abrasive, high temp environments. Hotmix or batch plants, whether natural gas, waste oil, fuel oil, etc.

* Cement – Filters for all areas of plant: kilns bag houses, silo bin vents, nuisance dust collection, etc. Our filters exceed all EPA emissions standards (NESHAP, CMAT, MACT for portland cement, PM2.5, etc.).

* Chemical – Filter fabrics for acidic or alkali compounds, corrosive or abrasive elements, etc. (lime, calc, fertilizer, plastics, etc.) – Special treatments and fabrics available. We can advise on the best combination for performance and cost.

* Food Processing – Food-grade fabrics construction available for dust collectors used in food production, transportation and packaging such as dust collectors on milling equipment, blenders, mixers, granulators, grain elevators, storage silos and more.

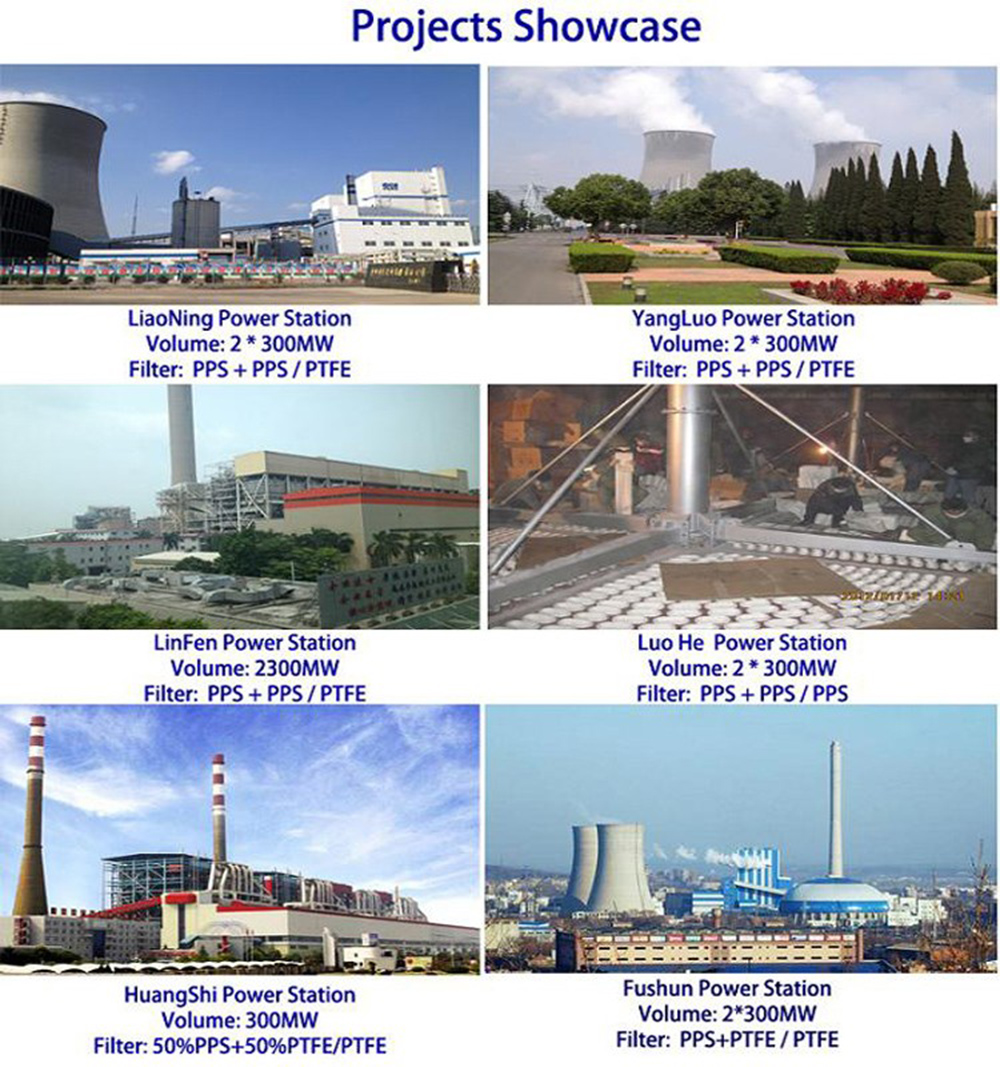

* Foundry and Metal Products – Filters for units used on arc/induction furnaces, casting operations, and precious metal reclamation. Fabrics and coatings for use in high temperature environments with need for high efficiency fume and smoke .* Power Generation and Industrial Boilers – Our filters exceed new EPA emissions regulations for boilers and power generation (Mercury and Air Toxics, Boiler MACT, NESHAPs, etc.). We have much experience working with biomass and coal power production facilities to overcome technical challenges to meet new EPA regulations. Filter fabrics and treatments include PPS, P84, PTFE/Teflon (fabric), fiberglass, and ePTFE membrane.

Package

Different types of filter bag must be individually packaged. In general, it is wrapped in plastic bags for water proof, then put in a carton. Filter bag must be neat and regular packing, with the ring of the filter bag to avoid ring flat compression deformation. For the requirement to keep the shape of filter bag, it must fill padding for filter bag inside. Any other packing ways also be accepted up to you.

7. FRQ:

1). Are you a manufacturer or trading company?

Manufacturer which located in Hefei,Anhui,China

2). What are your main products?

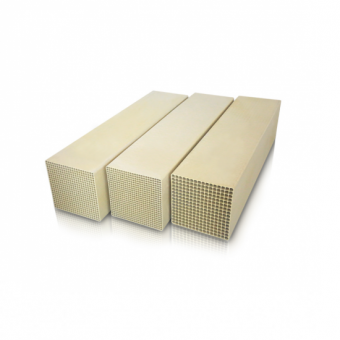

Needle punched felt, Dust filter bags, SCR Honeycomb Catalyst

3).What payment method can you do?

T/T L/C PAYPAL WESTERN UNION

4). What size can you do?

Customized sizes as you required.

5). Can you offer a sample before an order?

Yes, and it is a free sample

6). How can I order from you?

Step 1 You make the deposit after the Proforma Invoice finalized

Step 2 We start the production, and keep the communication with you if any questions

Step 3 You make the rest payment when the cargo is ready to ship

Step 4 We ship out the cargo, then offer documents