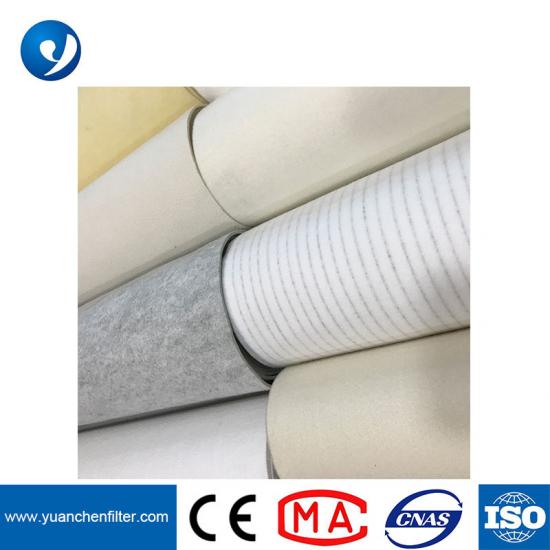

Industrial Dust Non-woven PTFE Needle Felt Filter Cloth

1.Brief Introduction Of PTFE Needle Punched Felt

Be composed of 100% pure PTFE;

Can operate at 240 °C continuously;

Acid and alkali Resistance, corrosion resistance,have strong chemical stability (0-14 PH)

Can be used under high humidity environment;

Low shrinkage rate even if under high temperature,

Aging resistance;

No enviroment pollution

2.General introduction of the PTFE Filter Fabrics

PTFE (polytetrafluoretyhylene) also called Teflon, which be treated as the KING of the plastics due to the properties of the high temperature resistance, corrosive resistance, durable, which is a innate excellent materials for industrial filtration.

Anhui Yuanchen adopted the first grade PTFE (Teflon) fiber and sound workmanship needle punched into felt, after the special finish treatment, the Teflon needle felt filter cloth can be widely used in various industrial occasions for dust collection (PTFE dust filter bag ) and liquid filtration (Teflon micron rated filter bag ).

3.Relevant specification for the PTFE (polytetrafluoretyhylene, Teflon) needle felt

Material: 100% PTFE (polytetrafluoretyhylene, Teflon) fiber, supported with PTFE (polytetrafluoretyhylene, Teflon) filament scrim

Weight:750~800 g/sq.m

Operation Temperature: Continues: ≤260℃; Peaks: 280℃

Surface treatment available: singed & glazed, heat set, PTFE suspension bath, PTFE membrane, micro pore size surface treatment.

We can customize the products according to the requirements from the clients!

Fibre Types

Operating temperature

Resistance to Hydrolysis

Resistance to Acids

Resistance to Alkalis

Resistance to Oxidation

Polyester

130°C- 150°C

restricted

good

restricted

good

Polypropylene

90°C- 100°C

excellent

excellent

excellent

restricted

PPS

160°C- 190°C

excellent

excellent

excellent

restricted

Aramid(Nomex)

204°C- 240°C

restricted

restricted

restricted

good

Polyimide(P84)

240°C- 260°C

good

restricted

restricted

good

Acrylic

125°C- 140°C

excellent

excellent

excellent

restricted

PTFE

250°C- 280°C

excellent

excellent

excellent

good

Fiberglass

260°C- 280°C

restricted

excellent

restricted

good

4.The properties of the teflon dust filter bags (made of PTFE filter media )

1.High temperature resistance, continuous operation temperature can up to 260 degree C, instant operation can up to 280 degree C.

2.Large-scale production available, with the much cheaper price when compared to the before.

3.Can be used at full PH range.

4.Long service life, as usual can be more than 4 years.

5.All of the production rang with various usage are available.

5.Application field:

Baghouse Filtration / Air Pollution Control System /Dust Collector

Foundry / Metal Smelting

Asphalt Mixing

Power Generation ,

Waste treatment power generation plant ,

Cement , Gypsum / Lime Processing

Mining.

Carbon Black.

Soap powder

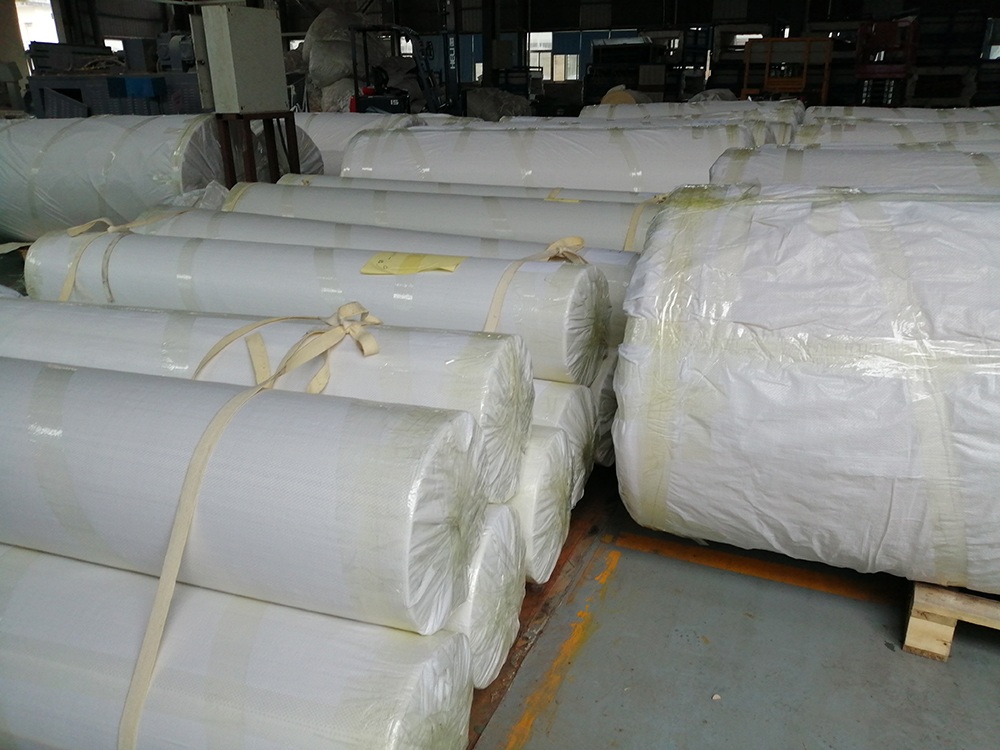

6.The dust felt filter materials packaging:

Usually packed into a PE bag in case of meeting damp,then into a nylon bag

FRQ:

Q1. What is your terms of payment?

A: T/T will usually be accepted,details could be negotiated.

Q2. What is your terms of delivery?

A: FOB, CFR, CIF, DDU,EXW

Q3. How about your delivery time?

A: Generally, it will take 10to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q5. What is your sample policy?

A: we could offer the sample for free charge but do not pay the cost of freight.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.