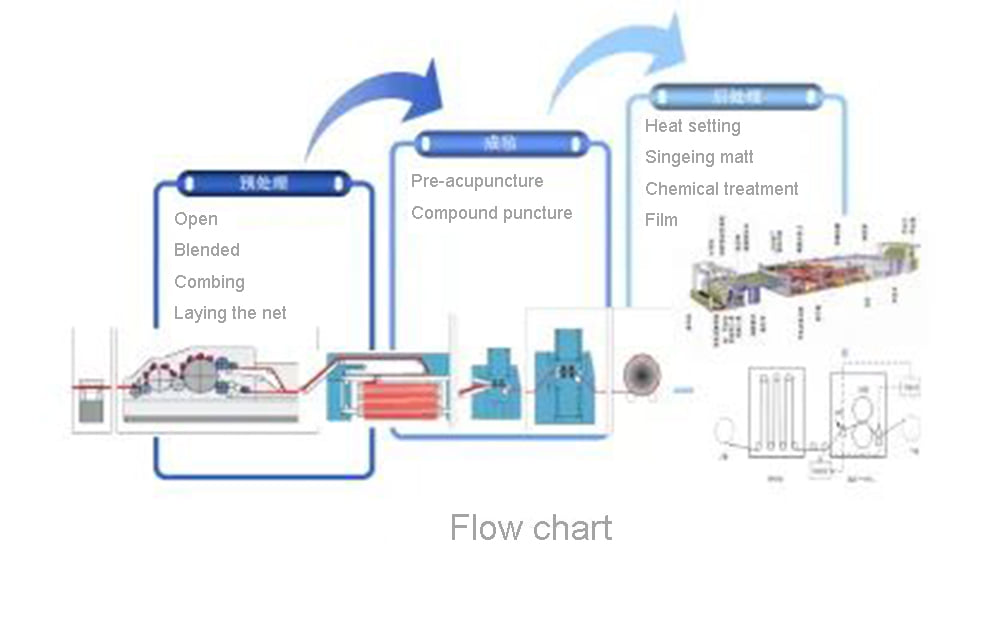

The post-finishing process of needle punched non-woven filter material for bag filter mainly includes singeing, calendering, dipping, heat setting, laminating and so on.

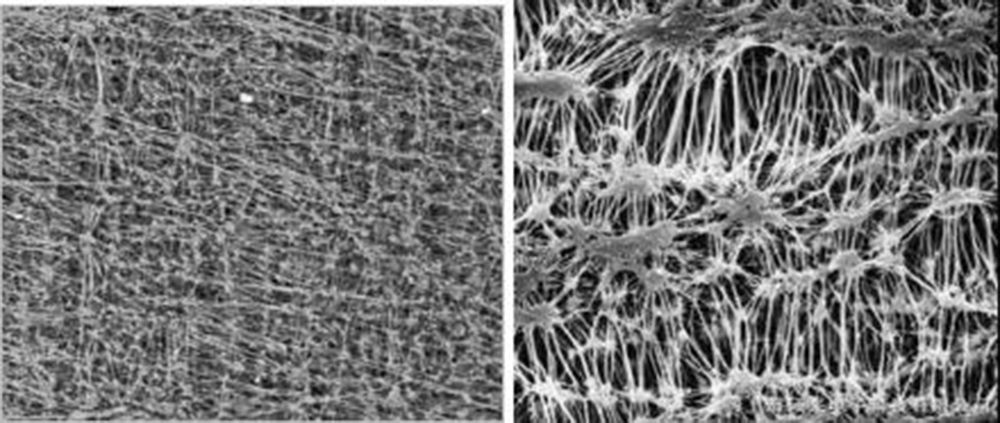

The filtration of the membrane filter material is carried out on the surface of the membrane, which is different from the deep filtration of the ordinary filter material. It belongs to surface filtration. Under normal working conditions, the filtration efficiency of the membrane filter material can reach 99.99%, and the discharge accuracy below 5mg/Nm3 can be controlled.

The membrane material used in the membrane filter material is mostly polytetrafluoroethylene (PTFE) microporous membrane, which is divided into high temperature membrane and normal temperature membrane. The PTFE microporous membrane is attached to the filter material using high temperature and pressure. For thermoplastic fiber filter media, the adhesive force generated by the remelting of the melt on the surface after uniform singeing has a positive effect on the film fastness; for thermoset fiber filter media, the PTFE microporous membrane can be pasted after special surface treatment. Close together firmly.

PTFE microporous membrane has all the characteristics of PTFE material. Yuanchen Technology adopts imported Tokuden electromagnetic heating laminating machine, and uses the "high efficiency and low resistance" laminating technology independently developed by Yuanchen Technology to firmly bond with PTFE fiber filter material. It can effectively improve the filtration performance of the filter material and meet the ultra-low emission below 5 mg/Nm3.