Stainless Steel Dust Collectors Filter Bag Cage

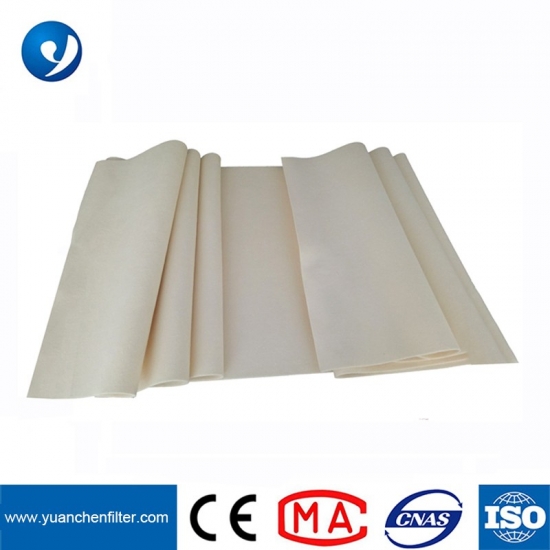

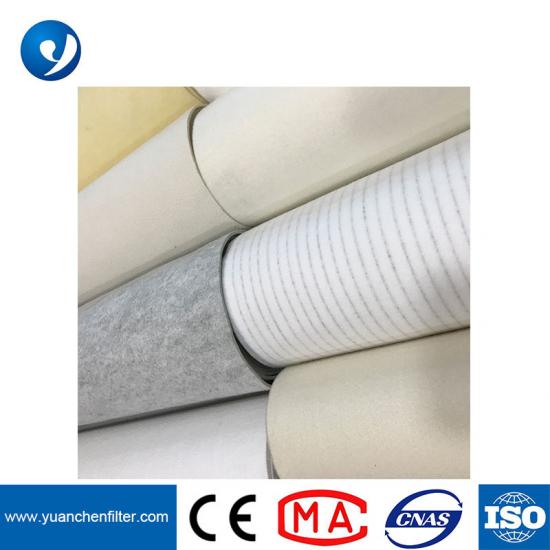

Product Display

1.no corrosion

2.no damage

3.3-5 times longer life than other bag Cage with steel

4. economical maintenance(almost no Maintenance required)

5.prominent effect in removing dust from Filter by pulsing

6.easy to install

7.no ventury installation required

Manufacturers Baghouse Framework Filter Bag Cages For Dust Collector

|

Application |

Industry Dust Collector |

|

Dimension |

Customized |

|

Lead Time |

Negotiated |

|

Raw Material |

Galvanized carbon steel wire |

|

Rod Diameter(mm) |

Φ3.0, Φ3.2, Φ4.0, etc |

|

Ring Diameter(mm) |

Φ4.0,etc |

|

Part Qty |

2 |

|

Accessory |

venturi |

|

Connector type |

rotary connector |

|

Finish treatment |

none |

|

Package |

simple steel frame case or full-cover steel frame case |

|

OEM |

Customized by your drawing |

|

ODM |

Yes, we do |

Dimension Recommended

A.Round Style

|

ΦDiameter |

Bag Diameter |

Length |

|

115 |

120 |

2000 2400 2800 3200 3600 4000 4400 4800 5200 5600 6000 |

|

125 |

130 |

|

|

147 |

152 |

|

|

195 |

200 |

B.Flat Style

|

Perimeter |

Bag Perimeter |

Length |

|

800 |

800 |

2000 3000 4000 |

|

900 |

900 |

5000 6000 |

C.Envelope Style

|

Length Width Thickness |

Bag Length Width Thickness |

|

1500*750*25 |

1500*750*25 |

Our service - Industrial dust collector bag filter cages with venturi tube

1. Enquiries quickly reply within 24 hours.

2. After-sales service, rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours. We can arrange professional engineers arrived at equipment location within 48 working hours for problem solved.

3. The dust collector design according to the specific condition of dust removal technology. The wind network project design for all system. To be the optimal structure design.

4. The lowest equipment price whole network in alibaba Welcome to rate of the price. If our price is higher, we will return twice of our quoted price difference to you. Please prompt before sign the contract with us. Due to our good faith principle.

5. The bag filter equipment over 20 years working life.

6. Associated with equipment spare parts, ensure the replacement parts within 20 years.

7. If accessories stop production or update, to ensure that the replacement parts can be normal use, and keep noticed one year before the spare parts stop production.

8. Ensure easy operation and absolutely no worries about future

Pack and Delivery of Galvanized Dust Collectors Filter Bag Cage

FRQ

1. Q: Are you a factory or a trading company?

A: We are factory and exporter since 2005.We have an improvement team from design, manufacturing ... to installation, commissioning and personnel training.

2. Q: Where is your factory?

A: Our factory is located in Hefei City, Anhui Province.

3. Q: How does your factory perform quality control?

A: We test the machine before shipment. Our factory has obtained ISO9001: 2008 certification.

4. Q: How long is the warranty period?

During use, two years warranty and free consultation.

5. Q: How to pay for the product?

Provide letter of credit, wire transfer and Western Union.